May 16, 2023

Trailside Farm weathers challenges, reaps rewards in first season

For those in the organic know, it is only natural to ask the grower at a newly established, transitioning-to-organic farm about previous uses of the land and soil.

I have certainly received this question about the farm I manage, and my response typically raises a curious facial expression from those asking. Concern and surprise come to mind, doubt as well.

I will explain: Our soil is from a streambank. This means that the soil is new and brought from off-site.

In the case of the Trailside Organic Farm located outside of Lebanon, Pennsylvania, building a farm and transitioning to organic is certainly a unique scenario. However, it is possible that the details of our project might spark interest from growers who are limited by the amount of farmable land in their area, and those willing to try a route that has not yet been heavily traveled.

Trailside was founded as a partnership between continuing care retirement community, Cornwall Manor, and Rodale Institute. As the first-of-its-kind, the Trailside Organic Farm’s objective is to provide fresh and healthy produce to residents and employees of Cornwall Manor. The finished farm-site will serve as a functional production operation while also adding aesthetic value to the campus.

Neat landscaping and a barn, thoughtfully styled as a homage to local historic Pennsylvania German architecture, are planned to be hallmarks of the Trailside site. A well, irrigation system, heated greenhouse, hoop houses, and eight-foot-tall deer fencing are infrastructure additions planned for the farm’s development. Further, regular workshops, volunteer opportunities and tours are also provided as part of the farm experience for supportive and enthusiastic Cornwall Manor residents. Raised bed allotments for residents will also be placed on the farm site.

The growing space at the Trailside Organic Farm covers 2.6 acres of land alongside the popular Lebanon Valley Rail-Trail, with the total available farm site footprint covering about 6 acres. Aside from woody growth, the hilly site was previously used to store construction debris from various projects over the years, adding to its challenging terrain.

Casual observers would consider the previous state of the land to be marginal, and they would also have trouble picturing rows of tomatoes and lettuce growing successfully when the idea was first conceived. In the spirit of determination and working with what was available, the lot was cleared.

New-to-us soil

Our small, diversified vegetable farm was constructed during the summer of 2021. The site was built up and graded, with construction fill serving as the base. Soil from a local streambank restoration project was trucked in and spread across the site This work created a uniform, downhill-sloping field.

The amount of soil trucked in was immense: Enough to cover the five-plus acres with 6-8 inches of soil. Keeping in mind that our soil source was a streambank, the sort of rocks, roots, stumps, and branches found in such a location were in our topsoil as well.

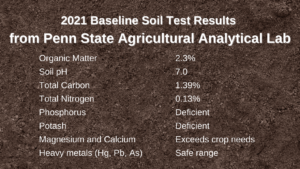

This meant that hand-picking of the field was in order after a thorough disking. Dominated with fine, clayey particles, our soil certainly has the propensity to become slippery when wet and to stay packed-down and hard when it dries. Proper soil management practices, especially amending with generous amounts of compost, were marked as priorities moving forward. Soil samples were sent to a local agriculture laboratory for analysis.

First friend on the farm

I began work at Trailside Organic Farm when it was an empty field during the fall and winter months. The winter rye cover crop I planted during November 2021 settled in sparsely despite a generous broadcast rate. Erosion was evident, with ravines forming on downhill- sloped areas of the farm.

Regardless, with an acre of production planned for the 2022 season, we had to begin growing somewhere. My first thought was to order a tool to help us start small and expand outward: A 16- foot by 48-foot hay grove-style caterpillar tunnel kit from an online retailer. This was to be built at the bottom of the farm site, the closest possible spot to the nearest water hydrant located one-third of a mile away.

The hay grove design allows for no additional baseboard lumber expense, and the sides may be rolled up or put down in just minutes for ventilation or lack thereof. This structure allowed us, with little upfront expense, to learn how plants grow in our soil without the added obstacles of early spring rain and mucky soil.

Katie Landis, assistant manager of the project, joined the team and helped me build the tunnel. Before planting, we added three more inches of higher-quality topsoil, about an inch of leaf compost, and tilled with a small, borrowed, walk-behind rototiller. We were on our way, and something now existed on our empty field. This was a magnificent sight.

Inside the tunnel, we grew our first-ever crop in the spring of 2022, a small selection of lettuce which was received as a novel and exciting addition to the salad bar for employees and residents of Cornwall Manor. Keeping with the salad bar, we used the tunnel to grow cherry tomatoes in the summer, with successful results.

Certainly, our lettuce and tomatoes showed minor signs of stress and slower-than-optimal growth due to low nutrient and organic matter levels in our soil, but nonetheless produced and tasted wonderfully. We were pleased with our harvests accumulated from our first shots at growing in the soil, though we hope to improve yields moving forward. For reference, during our 2022 season, we produced nearly two pounds of cherry tomatoes per bed foot planted, and almost a quarter pound of lettuce per bed foot planted.

The tillage question

Considering our soil profile, the choice of tillage equipment was a tricky one. This is especially true since research proved to be futile: There is not very much documented experience available from other farmers with a soil situation.

Because of the hardpan, rocky characteristics of the base layer of soil 6-8 inches below the top layer, a chisel plow is out of question since it would more than likely just bite into this sublayer, bog down the engine of our sub-compact 50- horsepower tractor, and cause damage to equipment. A moldboard plow may have been a better solution, but I was still unsure of its tendency to also lock onto the under-portion and bring our tractor to a halt.

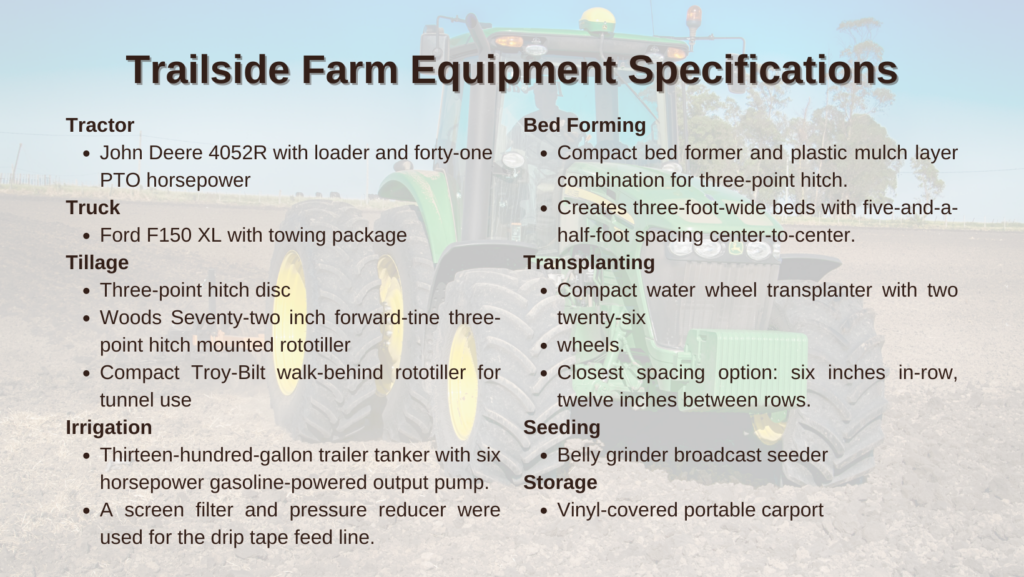

I decided, for the time being, that it would be best to avoid tillage deep enough to contact anything but the top layer of soil. A disc and a forward-tine seventy-two inch three-point-hitch-mounted rototiller were the tools of choice.

Composting and cover cropping

Co-mingling of the two layers is a goal for the future of the farm site, but this is something that will also take non-mechanical means of soil management and, most importantly, time. Our first soil health improvement steps have been increasing the organic matter by composting generously on the top layer, and by planting a variety of bulky cover crops.

Access to municipal leaves continues to be an ideal source of cost-effective organic matter and turning with the tractor bucket causes leaves to break down in three-to-four months’ time. Since the upper portion of our farm site was not used as cropland during our 2022 season, we instead kept it in living cover. An overwintered crop of rye survived into spring of 2022, at which point we tilled and sowed a pea and oats mixture.

During the fall, we turned over the soil to introduce a tillage radish cover crop in effort to break up the hardpan. Peas and oats eagerly re-seeded themselves at this point, sprouting alongside our tillage radish. In addition, we integrated buckwheat and crimson clover into empty spaces of our farm, with varying results.

We will be continuing to experiment with a variety of cover crops at the Trailside Organic Farm, seeking to increase organic matter in our soil, add nutrients, and break up our hardpan. Composting and cover cropping are also noted for increasing the microbiology present in soil, and we hope that more microbiology will also help to blur the line between these two layers over future growing seasons. Once soil health allows it, we also plan to incorporate a permanent bed system for greens, herbs, flowers, and direct-sown crops.

Controlling rainwater

Soon after we built our caterpillar tunnel and took delivery of our tractor-mounted rototiller, we began with initial tillage of our six planned field blocks of crop families: Solanaceous, allium, cucurbit, brassica, corn and potatoes. Much like the tunnel, we added compost and some higher-quality topsoil, both of which were tilled in.

However, after planting lettuce in the tunnel, I soon realized that I could keep raindrops from hitting beds, but I could not control the beds from soaking up rainwater collected around the tunnel’s footprint. Upon arriving at the farm mornings following overnight downpours, it was clear that our hoop house tended to become a sponge.

This was our first experience with our slow-to-drain soil properties, with a base clay layer that prefers to hold water rather than allowing it to infiltrate. We noticed that untilled field perimeters, buffers and driving paths did not soak water but instead slicked it off and sent it to the tilled beds which have also been composted, meaning that they hold quite a bit of water. This trend was especially true for sloped field blocks, and rainwater tended to collect in downhill corners and sit wet for extended periods.

As we became familiar with the site, we began to learn where water collected. We tried our hands at re-routing it. Some observation during thunderstorms was helpful. Using our slope as an advantage, digging trenches around fields was moderately worthwhile, although it required hand shoveling. Trenches helped flood waters to flow downhill and away from our field blocks rather than inside of our beds.

Of course, even in the absence of floodwater, raindrops still soaked into our empty but recently tilled fields and caused a muddy situation. Two things were needed before bed forming and planting: A week-or-so of dry and sunny weather and raised beds under plastic mulch.

A plastic-culture raised bed system seemed to be the best solution for helping our soil keep an ideal moisture level during wet conditions. Further, raised beds increase soil depth above our hard-packed and minimally pervious sublayer, allowing for more soil volume and thus moisture holding capacity in the plants’ root zones. Additionally, plastic mulch certainly seemed to help with evacuating excessive rainwater from our beds’ surfaces during heavy rains, instead routing much of the rainwater into aisleways.

Drip tape to the rescue

Drip tape is revered as an excellent solution to delivering moisture to the roots of plants when water is a limited resource. Since we needed to rely on our pickup truck and a water trailer as our inaugural season’s water source, going with drip seemed like the best and only choice.

Filling of the tank was completed with a garden hose at a hydrant intended to water flowers at a mail kiosk in the adjacent Cornwall Manor community. Roughly one hour was required to put roughly 350 gallons into the tank. Our pickup truck could safely tow around 500 gallons maximum, and about 15 minutes of driving and maneuvering was required to get the tank to and from the farm.

While making three roundtrips on those hot and sunny days, we were an entertaining but somewhat-disruptive sight for residents as our tank rattled over the speed bumps. Given the circumstances, this meant that every drop was valuable when running our irrigation. Early in the season, I picked up what would be considered a standard drip tape option: 12-inch emitter spacing putting out 0.45 gallons per minute per 100 ft of tape.

Soon after transplanting the bulk of our long-season crops, our mucky spring soil transformed to an arid growing medium during an extended span of rainless weather and summer heat. Especially when dry, a fine soil with low organic matter does not like to absorb and evenly-distribute moisture. I began to observe that most of our drip tape emitters were creating a small muddy puddle of water which drained into the nearest crack or depression, thereby exiting the bed rather than soaking through it and getting to plant roots. Longer durations of running the irrigation system resulted in larger muddy puddles, but not a bed that was ideally watered.

Betting it all on drip tape was a decision that required supplemental hand-watering with a simple greenhouse hose and water breaker to ensure water is going where it is needed: through holes in our plastic mulch and to the roots of our plants. Of course, hand-watering added many additional hours tending the farm during the summer months.

Choosing the correct drip tape for the soil in question is imperative, and I urge growers in a similar situation to spend plenty of time considering their irrigation plan. Next year, we will be trying drip tape that offers closer emitter spacing and a lower output to remedy these issues. Since we will also have an irrigation system and water shortage will be less of a concern, I plan to also try wobbler-type sprinklers with our direct-sown crops.

A word on facilities

When considering beginning a farm in a non-traditional location, having the land available is a large piece to the puzzle but not the only one. The creativity and flexibility concerning farmland must also extend to supporting facilities.

For us, this took the shape of a cheap, portable vinyl-covered carport for storing supplies and equipment during our first season. Although a heat-trapping

haven for stink bugs, we would have struggled without having a covered structure at the farm site.

My favorite part of our very first farm season was getting to re-purpose a vacant residential home to be a packhouse, flower shop, office headquarters and storage depot. Its location, alongside residential houses and about one mile from the farm site, could be tricky at times. However, with minor modification of the interior space, it proved to be wonderfully useful, efficient, and completely unassuming on the outside. Few people in the neighborhood knew quite what we were up to inside this space.

We began by stripping the upstairs bedrooms of their carpet and applying waterproof paint over the wood floors. The maintenance staff at the manor helped with installing three utility sinks side-by-side, tapping available water and drain lines to create a makeshift three-bay sink setup. We were given four spare residential refrigerators and placed them around the living room to refrigerate our produce.

Rooms were assigned with the following purposes: The washroom, the drying and storage room and the packing and weighing room (which also happened to have our refrigerators mixed in). This was all arranged while keeping the kitchen untouched for convenient lunch breaks.

Foldable tables in empty space allowed us to arrange flower bouquets, ripen tomatoes, complete paperwork and pack produce. With the construction of a greenhouse planned for 2024, the basement of our house will also be used as a grow room for beginning our farm transplants from seed for our 2023 season.

Onward!

“We’re still working on it.” That is the only phrase to end with. Something as full-of-life and dynamic as a farm takes time to establish, and, likewise, I believe that learning the best management practices for any plot of land takes time as well.

One thing is for certain, however. We are extremely fortunate to have the support of the incredible Cornwall Manor community of residents, employees and leadership. This project is only possibly with their support which comes in many different forms.

Although we are still learning and growing, the Trailside Organic Farm is not going anywhere anytime soon. Please check in with us in a few years!